Intergalactic wins U.S. patent for its proprietary microtube heat exchanger for aircraft and spacecraft

Press release archive

Wide-ranging patent covers general design, manufacturing process, and a broad array of applications of microtube heat exchangers in defense aerospace, civil aviation, and space contexts

ST.GEORGE, Utah – December 6, 2022 – Intergalactic, maker of the most advanced thermal management systems for space and sky, today announced that the U.S. Patent and Trademark Office has issued U.S. Patent 11,519,670 to Intergalactic for its proprietary microtube heat exchanger technology.

The patent protects “laser-welded microtube heat exchangers in aerospace environmental control systems,” which applies to any aircraft or spacecraft thermal management application. This includes, but is not limited to, electronics cooling or heating, aircraft or spacecraft habitat thermal conditioning, temperature regulation of mechanical systems such as engines or transmissions, bleed air cooling, and similar applications in the defense aerospace, civil aviation, and space sectors.

“We’re proud to have pioneered and perfected microtube technology for airborne and space applications,” said Intergalactic CTO Nick Kaiser, who is listed as an inventor. “Our microtube technology and manufacturing processes are critical to reducing the size and weight of high-performing thermal management systems required to deal with rising heat loads. We’re grateful to have our work on this innovation recognized with a U.S. patent.”

The patent covers the general design, manufacturing process, and various applications of microtube heat exchangers in air and space contexts. Specifically, the patent protects:

- Use of all fluids in microtube heat exchangers, including air, liquid coolants, oil, refrigerants, and more.

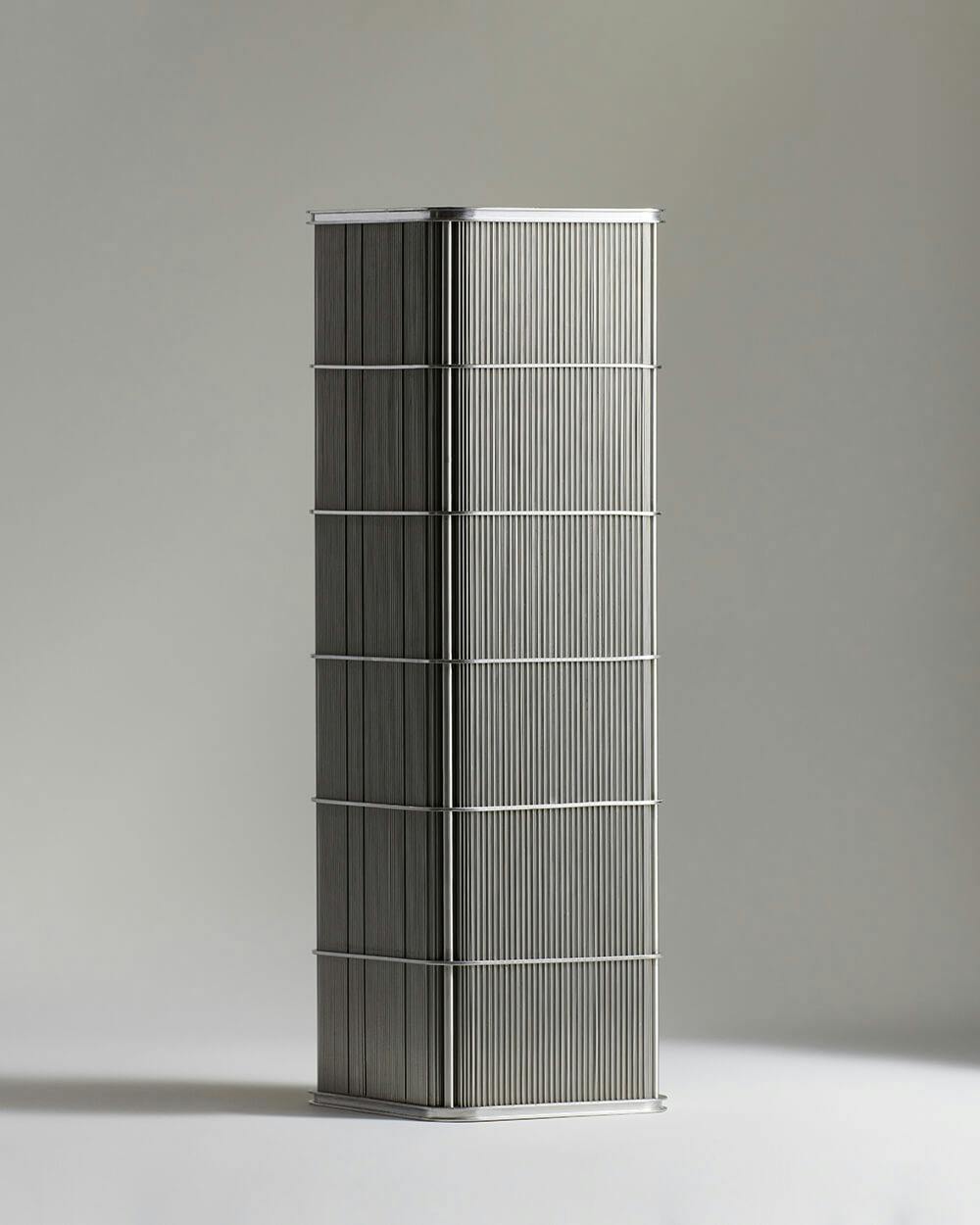

- Intergalactic’s proprietary construction style, which consists of end plates with holes, multiple microtubes between the plates, all laser welded together.

- A broad range of applications, including various fluid types and flows (including liquid, ram air, and more), mid-plates for flow direction control, tube reinforcement for protection against foreign object debris and damage, and various tube bank geometries (e.g. square, curve, arc, U-shape, and others).

- Various tube arrays and spacing patterns.

- Specific coverage of ram air duct installations which are common in next-generation defense aerospace applications.

Intergalactic’s microtube heat exchanger is a step change innovation, applying a novel laser welding process to improve robustness while unlocking significant size and weight savings without compromising performance and reliability, even in the most demanding environments and conditions such as those found in MIL-STD-810 and DO-160. As Tony Ho, Intergalactic’s Head of Systems Engineering, wrote in SAE Mobility Engineering:

Intergalactic routinely observes that microtube heat exchangers have shown 3x to 4x the capacity of a conventional plate fin heat exchanger for the same core volume. Alternatively, if one is more sensitive to weight or volume, one could shrink down the size of a microtube heat exchanger to maintain the same performance as a conventional heat exchanger, but significantly reduce weight and installation footprint. In real-world aerospace applications, Intergalactic has seen 50%-80% reduction in weight and/or volume for microtube heat exchangers compared to conventional heat exchanger technology.

In addition to offering considerable weight and size benefits, Intergalactic’s microtube heat exchanger has proven extremely durable even in the most adverse conditions. It is rated TRL-8 and has been field tested at Mach 1, 27 G’s of force, and 14,000 PSI. It is central to all Intergalactic’s branded, off-the-shelf thermal management systems.

Intergalactic’s microtube heat exchanger won first place at the 2022 Utah Innovation Awards in the advanced manufacturing, construction, and design category. It’s available in virtually any form factor and branded as Boreas3 for defense and civil aerospace applications and BoreasX for space applications.

For more information on Intergalactic’s full suite of thermal management solutions for space and sky, visit www.ig.space.

###

About Intergalactic

We’re on the verge of a new era in space and sky, with innovation happening at a rate not seen since the Space Race. But innovation requires breaking barriers, and in space and aviation, heat barriers are among the most formidable. That’s where Intergalactic comes in. We’re an aerospace systems integrator pioneering the smallest, lightest, and most advanced thermal management solutions in the space, defense, and commercial aviation sectors. We engineer and integrate next-generation subsystems, proprietary equipment, and intelligent software to enable boundary pushing performance and unrivaled reliability in space, sky, undersea, or on land. Learn more at www.ig.space.

Media contact

Brad Plothow

Chief Growth Officer

Bradp@ig.space