An introduction to phase-change thermal capacitors and thermal batteries

Blog

What do your granny’s hot water bottle, the cubes of ice in your Dirty Dr. Pepper, and the stones used to cook kalua pork all have in common? They’re all thermal batteries. They store and release thermal energy to produce a desired result. Today’s phase-change thermal capacitors and batteries used in aerospace and aviation function similarly, just in much more specific voltage and/or temperature ranges, and they make the previously impossible… possible. Let’s have a quick look at these seemingly magical technological marvels.

How phase-change materials allow thermal batteries and capacitors to store and release more energy

Granny’s hot water bottle and the fire-heated rocks various cultures use to cook food don’t change phases at all… they are liquids and solids, respectively, and they stay that way. They depend on the insulative properties of water and stone to absorb heat energy and release it gradually over time. Similarly, ground heat exchanger systems utilize a section of earth to absorb heat (usually via high-temperature fluid running through a network of pipes underground). Later, energy stored in this thermal battery can be removed by running a lower-temperature fluid through the pipes. This type of storage and release of thermal energy is fairly easy to understand, even for those of us who aren’t actually rocket scientists, but it has been part of the plans for long-term outposts on the Moon (or even Mars) as part of the ongoing Artemis missions.

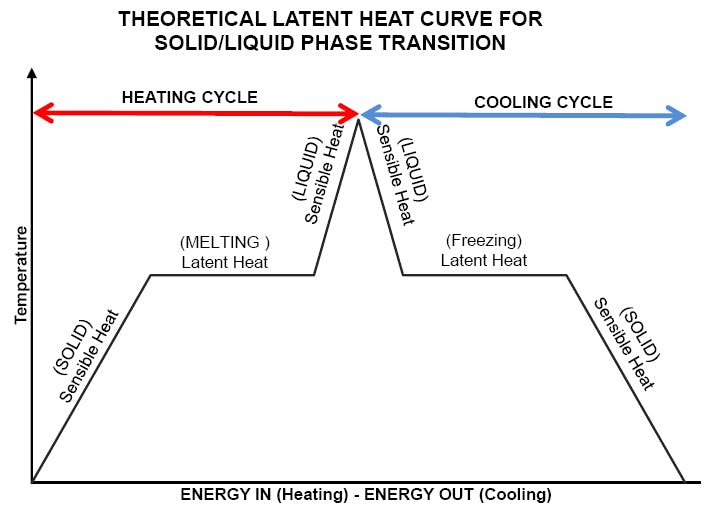

However, today’s advanced phase-changing thermal batteries and capacitors take advantage of what seems like a loophole in the laws of thermodynamics. As Dr. Emily Goddard of Sunamp explains, using a phase-change material (PCM) allows you to store more energy in the same volume when compared with a non-phase-change material. This is because, when you use a phase-change material, you take advantage of not just the sensible heat of the material, but also the latent heat available across the phase change. Sensible heat is where you store energy in either the solid or liquid phase of a material, while latent heat is stored across the change from solid to liquid or vice versa. Or, for those of you who (like us) couldn’t remember this bit of your high-school physical science class, sensible heat is what can be felt, and is defined as “the amount of heat or energy required to change the temperature of the substance without changing the phase of the substance. At a constant temperature, during phase transition, the amount of heat absorbed or released is called latent heat.”

Image courtesy of ChemicalOnline.com

Stated simply, storing energy over a phase change means you can store a lot more heat energy over a smaller temperature range. In practical terms, this means you can use the same volume of PCM and store around 4 times the amount of energy in it. Or, to put it another way, to store the same amount of energy, you only need to use about a quarter of the material if you use a PCM. For aviation, aerospace, and defense, where the weight and size of each component is thoroughly scrutinized, this is incredibly beneficial.

PCMs can be broadly categorized into 4 main groups: Metals and alloys, salt hydrates, plant-based PCMs, and paraffin/non-paraffin waxes.

Phase-change thermal capacitors and batteries in aviation and aerospace

Imagine you had to design an electrical system that needed to reliably function independently of the power grid, and millions of lives were at stake. Imagine this system needing to stay at the ready for years or even decades of time, without any input of external energy, but having to perform at a moment’s notice with near 100% reliability. What could you do? Well, the smart folks that designed the large guided missiles and nuclear weapons that have both kept our nation safe and terrified several generations of human beings often used molten-salt phase-change thermal batteries to provide the necessary electrical power.

These non-rechargeable electrical batteries contain a low-melting eutectic PCM mixture of ionic metal salts (usually sodium, potassium and lithium chlorides, and/or bromides) used as the electrolyte of the battery. (A eutectic mixture is a homogeneous mixture whose melting point is lower than that of its constituents.) These batteries are manufactured with the salts in solid form, and as long as the salts remain solid (with the storage temperature and humidity remaining within an appropriate range), the batteries have an astonishingly lengthy shelf life of up to 50 years, while retaining nearly full power upon activation. This provides obvious benefits for guided missiles and ICBMs that are stored and (hopefully) rarely or never used, but need to remain functional. When the batteries are needed, the salt-based electrolyte is quickly melted and activated, usually by a pyrotechnic heat source during the ignition sequence. Molten-salt batteries have proven very reliable and have a high energy density.

Another, less destroy-the-world way PCMs are used in aviation is in the heat sinks used for regulating the heat of electronic components such as the radio frequency (RF) power amplifiers for WiFi systems onboard airliners. These electronics are asked to perform across a wide range of temperatures, including very cold temps at 35,000 feet, and potentially sweltering temperatures sitting on the hot tarmac of a sunny airport.

As Celsiainc.com explains, “The challenge then becomes one of designing the lightest and smallest heat sink for a duty cycle where 90% of its operational time is at very moderate or even cold ambient temperatures with only 10% of its time at elevated ambient temperatures — generally less than 90 minutes for this application. This is where phase change material comes into play.”

In this application, a phase-change material as simple as paraffin wax is utilized inside the heat sink connected to the RF amplifier. Keeping the RF amplifier cool is relatively easy with a lot of cold air available at altitude (perhaps using forced-air cooling), but during the 60 to 90 minutes the aircraft is sitting at the gate on the hot tarmac in ambient temperatures up to 122°F (50°C), the heat generated by the electronics can quickly exceed the ability of the heat sink to shed that heat to the ambient air. However, by incorporating a paraffin PCM into the heat sink design, as the heat sink temperature rises to the melting point of the wax, the phase change of the paraffin effectively absorbs the excess heat. Just like magic. (Note, we’ve been commercializing this technology for various aviation and space applications, including eVTOL, regional electric aircraft, and lunar mobility vehicles. Check out the image below from one of our testing sessions -- video also attached to this article.)

Phase-changing heat sinks have the additional benefit of being smaller and lighter than non-PCM heat sinks of the same thermal capacity, which as we noted earlier, is always a good thing when you’re trying to launch people and things into space.

Phase-change thermal capacitors are now widely used in the energy-storage panels and/or temperature-regulating systems of satellites. Phase-change thermal capacitors are also integral to such missions as ESA’s ExoMars orbiters and rovers. “ExoMars thermal capacitors are PCM-based heat exchangers using phase change waxes that transition from solid to liquid at the desired control temperature and absorb considerable heat energy in the process. In order to effectively transmit the heat into the PCM wax, which has very low conductivity of its own, the wax is contained within rugged, impact resistant, thermally conductive aluminum housings filled with an open-celled aluminum foam that acts both as a structural core material and provides a very large surface area for the wax to make contact with.”

For higher-performance military and aerospace applications, metallic PCM-based thermal capacitors are often preferred, as “Given equivalent external forcing, metallic PCMs absorb heat from an interface ~1 to 2 orders of magnitude faster than other classes of PCMs,” according to one source.

So, next time you order a triple-double, large fries (animal style), and a Diet Coke at the drive-through, be sure to ask for extra phase-changing thermal batteries in your soda.

–By Jeff Davis, Intergalactic Scribe

Sources:

https://celsiainc.com/technology/pcm-thermal-storage/

https://www.sciencedirect.com/science/article/abs/pii/S0306261919316423

https://ttu-ir.tdl.org/server/api/core/bitstreams/4ec0a911-1bd7-4e01-b9c8-cdc92e505afd/content