Check out how Intergalactic is innovating in two crucial areas: microtube heat exchangers and thermal systems for eVTOL

In the ever-evolving aerospace industry, innovation is the driving force that propels progress. Two distinct but equally groundbreaking advancements are poised to shape the future of aerospace engineering: Intergalactic’s patented laser welded microtube heat exchanger technology and the Eagle 5 thermal management systems for electric Vertical Takeoff and Landing (eVTOL) aircraft. These innovations share a common thread of pushing boundaries, enhancing efficiency, and redefining possibilities. Intergalactic is positioned to reshape aerospace technology by integrating these innovations.

Revolutionizing aerospace thermal management with laser welded microtube heat exchangers

Efficient thermal management is a cornerstone of aerospace engineering, ensuring the optimal performance of critical components under extreme conditions. Traditional methods, though reliable, often come with limitations in weight, volume, and heat transfer efficiency. Enter IG’s patented laser welded microtube technology, a game-changer in aerospace thermal management.

Microtube heat exchanger technology utilizes a large number of small, diameter-thin walled tubes to provide a very large heat transfer surface area in a small volume. This configuration allows for heat exchangers that are 50-80% smaller and lighter compared to a conventional brazed plate-fin heat exchanger, which was invented a century ago and has been the prevailing heat exchange technology in aerospace for 50 years or more.

Laser welded microtube technology leverages high-powered lasers to create precise joints between microtubes and heat exchanger header plates. Unlike conventional brazing or adhesive methods, laser welding ensures a strong and seamless bond which produces a very robust heat exchanger able to provide high reliability in severe aerospace environments. Further, this construction method and the use of microtubes enables intricate and unique designs which are compact and able to best utilize limited and unusual space found on confined aerospace environments such as eVTOLS.

The microtubes’ compact nature, combined with laser-welded precision, results in lightweight and space-efficient thermal management systems, critical factors in optimizing aerospace vehicle performance. Aerospace vehicles can operate in extreme conditions. Laser-welded microtube systems exhibit enhanced structural integrity, reducing the risk of failure in the most challenging environments. Additionally, the technology allows for intricate designs tailored to specific aerospace applications, offering flexibility in addressing diverse thermal management needs. Finally, the energy efficiency of laser welding, coupled with microtube systems’ durability, contributes to reducing energy consumption and waste during both production and operation.

Complexities of thermal management in eVTOLs and electric or hybrid-electric aircraft

eVTOLs rely on electric propulsion systems, creating heat during battery charging and discharging. Effective thermal management is vital for battery performance, health, lifespan, and passenger safety. Electric motors and power electronics generate heat during operation. Efficient cooling solutions are essential to prevent overheating and maintain optimal performance. Passengers’ comfort is crucial for eVTOL success. Effective thermal management ensures cabin temperature regulation, enhancing the travel experience. Dynamic thermal management systems are needed to accommodate varying thermal management needs based on missions, weather conditions, and altitudes.

Further, eVTOLS face even more significant Size, Weight, and Power (SWaP) consumption challenges than typical air or space borne platforms. SWaP has a direct impact on vehicle performance and range. Significant vehicle weight is allocated to battery systems. Solving this SWaP challenge is essential to the technical viability of these platforms. Additionally, these electric systems operate at voltage and power levels not seen before in aerospace driving the need for development of new electric power solutions.

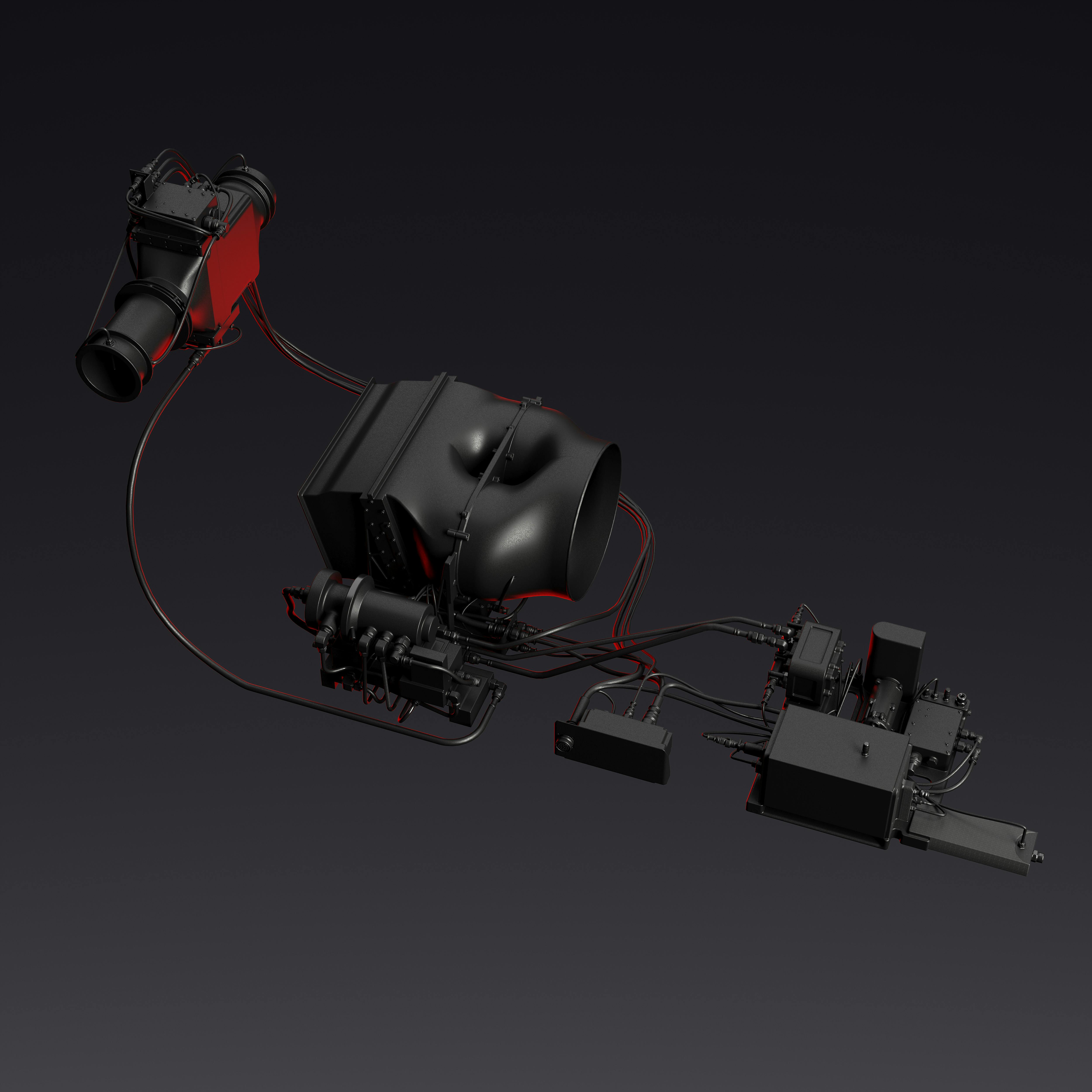

Intergalactic enables eVTOL platforms by providing efficient and reliable thermal management in a minimized size and weight footprint. This is accomplished by developing optimized integrated vehicle thermal management systems such as Intergalactic’s GS1-EV Eagle5. The Eagle 5 leverages laser-welded microtube heat exchangers, pumped two-phase battery and electronics cooling, phase change material thermal batteries, model-based design and optimization of thermal management systems and components, advanced lightweight materials, innovative high voltage DC power systems, and utilizing software intelligence for optimal efficiency and control.

Leadership in eVTOL thermal management systems

As the aviation landscape evolves toward eVTOL vehicles, Intergalactic is pioneering and leading the way in the next generation thermal management systems that can be tailored to the unique challenges posed by these innovative aircraft. At Intergalactic, we are not merely following trends; we are setting the standard for excellence.

The development and integration of effective thermal management systems has emerged as a critical differentiating factor for eVTOL manufacturers. The evolution of aviation from traditional combustion engines to electric propulsion introduces a host of thermal dynamics that demand precise and intelligent solutions. Intergalactic is not shying away from these challenges; instead, we are embracing them as opportunities to define the future of urban air mobility.

The trailblazing original manufacturing equipment (OEM) companies recognize that thermal management is more than just temperature regulation – it’s a fundamental pillar supporting safety, reliability, and efficiency of aircraft operations. Every aspect of an eVTOL’s intricate architecture, from battery health to passenger comfort, hinges on the success of its thermal management system.

True leadership is not just about developing systems that work – it’s about developing systems that excel. Intergalactic is employing advanced thermal sensing and modeling techniques to gain an intimate understanding of temperature variations across critical components. This insight-driven approach empowers OEMs to predict, prevent, and respond to thermal challenges proactively, ensuring optimal performance even in the face of dynamic operating conditions.

In the pursuit of excellence, the best eVTOL OEMs are not content with off-the-shelf solutions. They are reimagining the very fabric of thermal management through innovative heat exchangers designed for optimal efficiency and heat dissipation like Intergalactic’s patent laser-welded microtube heat exchanger. By embracing cutting-edge materials science, they are forging new pathways in material selection, ensuring that each component contributes to the system's overall thermal effectiveness.

At Intergalactic, we’re innovating in every aspect of aerospace thermal management, from the materials and components to the system design to the way we run our business. This focus on building the future is evident in our patented microtube heat exchanger and eVTOL thermal management systems, among others. These advancements exemplify the relentless pursuit of excellence in addressing complex challenges and pushing the boundaries of what is achievable. As these innovations continue to shape the skies and redefine aerospace engineering, they remind us that progress knows no bounds and that the future of aerospace is brighter and more promising than ever before.

- Nick Kaiser, Intergalactic CTO