The C-5 Galaxy (FRED): The revolutionary strategic heavy transport that almost tanked Lockheed

Blog

In the good ol’ US of frickin’ A, we like things big. Bigger burgers, bigger cars, bigger spending deficits, and crucially for the military, bigger aircraft carriers, mobile bridges, tanks, assault helicopters, and heavy transport aircraft to move it all around. After all, why get the job done with four existing airplanes when you can get the same job done with one new airplane at 50 times the price? Hell yeah! Today’s example of kickass American excess is the C-5 Galaxy, a transport aircraft so big, heavy, and expensive that it almost bankrupted the mighty Lockheed aerospace company. But danged if it don’t carry a lot of stuff (like 25,844,746 ping pong balls!). Let’s take a look at the mammoth C-5 and see if it’s worth all the trouble… and all the money.

So, just how big is this thing? Dimensions and carrying capacity of the C-5 Galaxy

The current C-5M has a maximum takeoff weight of 840,000 pounds (381,000 kg). To put that in perspective, the C-130 Hercules has a maximum takeoff weight of 155,000 pounds, the C-141 Starlifter’s max was 343,000 lbs, and the max takeoff weight of the C-17 Globemaster III (the next-largest heavy transport aircraft fielded by the US) is 585,000 pounds. The C-5M carries a fuel load of 332,000 lbs (150,819 kg) and has a cargo carrying capacity of an incredible 285,000 lbs (129,274 kg).

With an empty weight of 374,000 pounds (232,693 kg) and at 247.8 feet (75.53 meters) long, 65 feet (18.84 m) high, and with an impressive wingspan of 222 feet (67.9 m), the C-5 is a hefty boi, with a massive cargo hold 121 feet (36.8 m) long, 19 feet (5.8 m) wide, and 13.5 feet (4.1 m) tall. This space allows the transport of up to 36 loaded 463L master pallets, six Greyhound buses, two complete M1 Abrams tanks, three CH-47 Chinook twin-rotor heavy-lift/transport helicopters, or an entire C-130 Hercules transport airplane (with wings and tail removed, naturally).

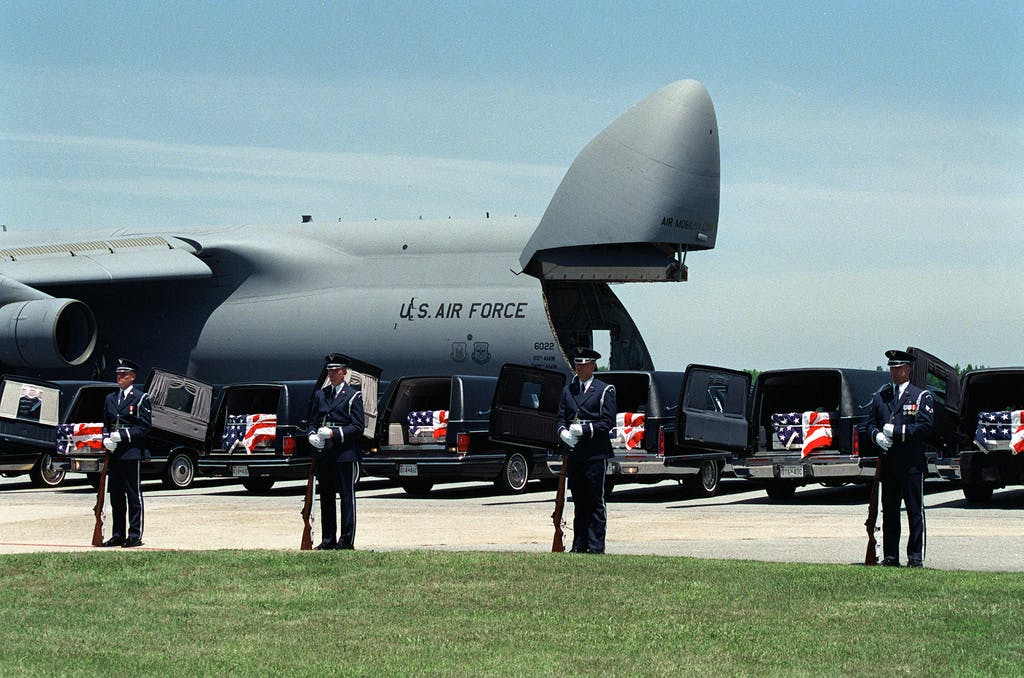

The C-5’s innovative lifting nose and high T-tail design allows both ends of the cargo space to be loaded or unloaded at the same time, and the ultra-complicated, 28-wheel landing gear can even “kneel” the aircraft down so vehicles can easily drive directly into the hold.

The C-5M is the only strategic airlifter capable of transporting 100% of certified air-transportable cargo. If it’s cargo rated to fly, it fits. It’s also said to be the only system capable of reaching America’s warfighters in any theater of combat on earth without refueling, though if you do the math this is a bit of a stretch. Lockheed says the C-5M, with a cargo load of 281,001 pounds (127,460 kg), can fly 2,150 nautical miles (2,474 miles), offload, and fly to a second base 500 nautical miles (575 miles) away from the original destination — all without aerial refueling. However, to put that in perspective, an airline flight from New York to London is 3,459 miles… so we’re assuming that “anywhere on earth without refueling” means you can start from Allied bases located elsewhere from the homeland, or at least within about 2,500 miles of the hot zone… or that you are transporting less than a full load of cargo.

However, sources vary. Defense Industry Daily reported that “Each C-5 aircraft can carry 265,000 pounds of cargo for 4,000 miles (roughly double that of the newer C-17A), or 125,000 pounds for 8,000 miles.” That’s more like it, though we would assume Lockheed would better know the true capabilities of the aircraft, since, you know… they built it.

The upper flight deck of the C-5 Galaxy (above the main cargo compartment) seats a cockpit crew of six, a relief crew of seven, and eight average-sized government bureaucrats if desired. There are also two bunk rooms with three beds in each room. The rear upper deck/troop compartment seats 73 passengers and two loadmasters. Both upper deck compartments are fully pressurized, air-conditioned, and incorporate galleys for food preparation as well as lavatories. The Aviation Zone points out that Christopher Columbus’s entire 3-ship crew of 90 could have ridden comfortably in the upper deck of the C-5, with room in the cargo area for animals, supplies, and smallpox (yikes!).

And since we’re hardcore environmental control systems (ECS) nerds in addition to aerospace geeks, we’ll point out that the self-contained ECS of the C-5 has a total cooling capacity of 24 tons, or enough air conditioning to cool eight average-sized American homes.

If desired, the C-5 can carry 270 passengers in the “air bus” configuration, in addition to leaving lots of space for cargo (and, incidentally, in 1971 Lockheed was planning on launching a commercial airline version of the C-5 called the L-500 which could potentially carry up to 1,000 passengers and would have competed with the Boeing 747. It never materialized due to financial and technical troubles, as we’ll see later).

A brief history of the C-5 Galaxy’s development

In the early 1960s, the US military began to see the need for larger, heavy-transport aircraft to support its efforts in Vietnam and elsewhere. The C-141’s cargo hold wasn’t large enough for some of the new military gizmos coming out, and better performance was desired. Several aircraft manufacturers and the Air Force spitballed designs, and by 1963 the agreed-upon conceptual design for the new heavy transport aircraft was named CX-X. It was to be equipped with four engines (instead of six in some earlier concepts), with a targeted gross weight of 550,000 pounds (249,000 kg), a maximum payload of 180,000 lb (81,600 kg), and a speed of Mach 0.75 (500 mph or 805 kph). The cargo compartment was to be 17.2 ft (5.24 m) wide by 13.5 feet (4.11 m) high and 100 ft (30.5 m) long, and serviced by front and rear access doors.

In 1964 the requirements were refined further and in April the initial request for proposal was released for the “Heavy Logistics System” (CX-HLS) (née CX-X). Initial requirements specified the aircraft be capable of carrying a payload of 125,000 pounds (56,700 kg) over a distance of 8,000 miles (12,875 km), or twice that load over a shorter distance. It also had to be able to operate, at maximum weight capacity, from the same semi-prepared runways and runway lengths as the existing C-141 (8,000 feet takeoff / 4,000 feet landing). A controversial specification was design-life factor for the wing, which needed to survive for 30,000 flying hours. This was unintentionally prophetic, as we’ll see below.

Multiple aircraft companies submitted proposals, but only Lockheed, Boeing, and Douglas made the initial cut, and in 1964 the three companies were given one-year airframe study contracts, along with General Electric and Pratt & Whitney for the new engine, which the Air Force had determined would need to be a new high-bypass design (more on this later).

After review the USAF considered Boeing’s design to be superior, but Lockheed underbid them and won the contract in December 1965, with General Electric winning the engine contract. The first C-5 first flew on June 30, 1968. (Interestingly, Boeing utilized their design for the CX-HLS competition, modified it so the wing was at the bottom of the fuselage rather than the top, and this became the iconic 747 passenger airliner. Way to turn those sour .gov lemons into commercially successful lemonade, Boeing!)

The C-5 Galaxy’s revolutionary General Electric TF39 high-bypass engines

Developed specifically for the C-5 Galaxy’s contract bid, the GE TF39 was the first high-power, high-bypass turbofan jet engine ever developed. This type of engine is the bread and butter of high-power, high-efficiency jet transport propulsion today, but the concept was revolutionary in the 1960s.

The bypass ratio of a turbofan jet engine is the ratio between the mass flow rate of the bypass airstream to the mass flow rate entering the core of the engine. A 5:1 bypass ratio, for example, means that 5 kg of air passes through the bypass duct for every 1 kg of air passing through the core. In this high-bypass design, the majority of the engine’s thrust is provided by the fan, rather than by the hot gases exiting the core.

The primary advantage of the high-bypass turbofan jet engine is that it provides increased fuel efficiency for the same thrust compared to legacy jet engines. The high-bypass turbofan design utilizes an axial fan compressor stage and has a much larger fan diameter than previous designs. All prior turbofan engines had a bypass ratio of 2 to 1 or less, while the TF39 achieved a bypass ratio of 8 to 1, and set the benchmark for all future transport aircraft both in military and civilian aviation.

It’s not all gravy, though, as the high-bypass design has some disadvantages, including increased engine size and weight compared to low-bypass turbofans or no-bypass turbojets, as well as a reduced or delayed throttle/thrust response. For this reason, high-bypass turbofans aren’t used on fighter or strike aircraft, which need to be able to quickly respond to rapid changes to the throttle in combat.

The TF39 was further developed and refined into the CF6 series of engines, and formed the basis of the LM2500 and LM6000 marine and industrial gas turbines, which are used in everything from electricity power plants to warships to hovercraft. The TF39 was groundbreaking for certain, but in aerospace has been supplanted by its posterity, and all remaining active C-5 are now powered by the more powerful and efficient F138 engines.

The original C-5 could carry 220,000 pounds of cargo… except, just kidding, its wings would break off

As you can imagine when building any large transport aircraft, weight is a serious issue that must be constantly wrestled with. The greater the weight of the aircraft built on the same basic structure, the less cargo weight it can safely carry. The initial flying development C-5 aircraft that were delivered under the contract-guaranteed weight, but due to necessary changes and modifications, that weight ballooned until by the delivery of the 9th C-5, its weight was over the guaranteed limit.

This extra weight contributed to an even worse problem than reduced operational payload: the C-5s wings started developing cracking during static and fatigue stress testing. In July 1969, during a fuselage/wing up-bending test, the C-5’s wing failed at 128% of limit load, which is well below the sustained 150% of limit load requirement. Lockheed scrambled to make changes to the wing, but during a test in July 1970, it failed again at just 125% of limit load. So, the existing fleet’s maximum allowable payload was reduced from 220,000 to 190,000 lbs (100,000 to 86,000 kg). At the time, engineers determined a 90% probability that no more than 10% of the fleet of 79 C-5 airframes would reach their fatigue life of 19,000 hours without the wings cracking.

The C-5A fleet was quickly restricted to carrying only 80% of maximum design loads. In an effort to reduce wing loading, a passive load alleviation system was added to the aircraft in the form of uprigged ailerons. But stress fractures continued to appear. By 1980, C-5 payloads were restricted to a comparatively pathetic 50,000 lb (23,000 kg) for general cargo during non-wartime operations. *Psh,* my grandma’s Oldsmobile can carry that much.

So, was the C-5 doomed to the scrap heap after all the initial expense? Nope! If there’s one thing we’ve learned in America, it’s that when you’ve thrown a lot of money at a program and it’s failing, the only logical move is to throw even more money at it! So a $1.5 billion program (equivalent to $7.7 billion today) called H-Mod was enacted to re-wing all of the completed C-5As to restore full payload capability and improve their service life. The H-Mod program began in 1976, and after thoroughly reviewing and testing the design and function of the new wing, all C-5As were upgraded with the new wing between 1980 and 1988.

The new wings took advantage of advanced aluminum alloys that were not available in the 1960s, and subsequent new-production versions of the C-5 incorporated these improvements in design and materials.

So what’s the deal with the C-5 Galaxy’s nickname “FRED”? What does it mean?

The US military loves its acronyms, and historically doesn’t have a real problem with profanity either. The C-5 earned the nickname FRED, or F***ing Ridiculous Economic (and/or Environmental) Disaster, due to its extensive and well-publicized cost and budget overruns. Gizmodo says, “Developing the C-5 nearly bankrupted Lockheed. Due to the plane’s massive size and complicated development cycle, the Galaxy program hemorrhaged money continually, which is why it has the dubious distinction of being the first military plane program incur a $1 billion cost overrun” from initial projections and approvals, and remember that was in 1968 dollars, equalling over $8 billion in today’s simoleons. The final unit production cost of the C-5B was $167.7 million ($352 million per plane in 2020 dollars). There were multiple hit pieces by the news organizations of the day targeting the wildly overpriced C-5 program.

Operational costs are high compared to other heavy transport aircraft as well; in fact the C-5 has the highest operating cost of any Air Force weapon system. Wearethemighty.com reports, “It costs more than $100,000 per hour to fly the [C-5]. And since it’s been around in its current form since 1995, they’re getting older and are starting to require more and more maintenance. Meanwhile, the much newer C-17 flies for around $24,000 an hour. It carries less cargo, but it carries that cargo more efficiently.”

Add to this the fact that for much of the 1980s the available load capacity was dramatically reduced (as discussed above), and flying the C-5 without using its large-size and full-lift capabilities didn’t really make a lot of sense.

One reason operational costs are so high is the multiple complex systems (not to mention the 100 miles of wiring used in the airplane) sometimes don’t play well together, as Air Force Magazine reported in 2004:

“The Galaxy also has major problems, as was glaringly apparent during one particular C-5’s trip from Dover to Europe. As it readied for takeoff, an engine warning light appeared in the cockpit. The flight crew taxied the airplane back to the apron, the passengers got off, and maintenance crews investigated. After the problem was fixed and the passengers had reboarded, the aircraft headed out again, but another warning light came on – this time during the takeoff run.

Five more times, the C-5 attempted to leave, and each time there was a glitch. Airborne at last, the heavily laden giant lumbered up to cruising altitude, but, some 100 miles out over the Atlantic, yet another warning light came on – this time, a landing gear door seemed ajar. The airplane returned to Dover for yet another repair. The C-5 finally reached its destination in Europe – but more than 18 hours late.”

Aviation historian Robert F. Door is quoted as saying, “After being one of the worst-run programs, ever, in its early years, [the C-5 Galaxy] has evolved very slowly and with great difficulty into a nearly adequate [emphasis added] strategic airlifter that unfortunately needs in-flight refueling or a ground stop for even the most routine long-distance flights. We spent a lot of money to make it capable of operating from unfinished airstrips near the front lines, when we never needed that capability or had any intention to use it.” This specifically hearkens to the STOVL capability the Marines specified for their variant of the F-35 Joint Strike Fighter. It has limited utility and greatly increases the cost and complexity of the aircraft, with questionable benefits (made even more poignant by the fact that the Navy and Air Force variants of the JSF don’t include it).

As for the “Environmental” part of the so-called disaster, it refers to its thirsty fuel consumption (despite the more efficient engines… the plane is simply massive), its need for lots of expensive maintenance, and its somewhat spotty reliability. Boeing’s 747 platform ended up being significantly more fuel efficient, with a much greater range (though it was of course optimized for passenger transport and not intended to take advantage of in-flight refueling systems like the C-5 can). The fuel crisis of the 1970s did nothing to help the situation.

In 2003 Air Mobility Command historians Leland and Wilcoxson wrote, “Consistently disappointing reliability rates, however, have prevented the C-5 from meeting the high expectations of political and military leaders who championed its importance to the national defense strategy. The C-5’s approximate 63 percent mission capable rate for fiscal year 2002 was the lowest of any AMC generic aircraft, and it fell considerably below the 75 percent mission capable rate the command’s organic aircraft must maintain if they are to perform most of their peacetime and wartime missions. So, too, have costly piecemeal fixes of disputed value furnished plentiful ammunition to the airplane’s critics.”

However, those critics would soon be somewhat mollified, if not silenced entirely, as the DoD signed the C-5 up for a hefty upgrade package for the 21st century.

The Reliability Enhancement and Re-engineering Program (RERP) and the C-5M Super Galaxy

The C-5 has undergone multiple variations and upgrades over the decades, including the aforementioned wing replacements and improvements to radar systems, landing gear, engines, and navigation systems. However, the relatively poor showing of the legacy C-5 in meeting target performance goals (along with congressional funding pressure to justify all the expense of the program and a study showing 80% of the C-5 fleet’s airframe service life was still remaining) spurred the Air Force to initiate an aggressive program to modernize the aircraft in 1998. The Air Force says, “The C-5 Avionics Modernization Program included upgrading the avionics to improve communications, as well as upgrading the navigation, surveillance and air traffic management systems to maintain compliance with national and international airspace requirements. It also added new safety equipment and installed a new autopilot system.”

As these improvements were rolled out and the Global War On Terror heated up, necessitating further improvements to the USA’s heavy-lift fleet, the Reliability Enhancement and Re-engineering Program (RERP) was initiated in 2008, wherein all existing C-5s would be refreshed with better-performing F138 (General Electric CF6-80C2) engines, with over 51,000 pounds of thrust per engine. This represents 22 percent increase in thrust and results in a 30 percent shorter take-off roll, a 58 percent faster climb rate, and allows significantly more cargo to be carried over longer distances. These rolling upgrades would take until 2018 to complete, but Lockheed Martin and the Air Force wasted no time in showing off the capabilities of their newer, better, C-5, termed the C-5M Super Galaxy.

On September 13, 2009, to showcase the improved performance of its top-line heavy transport aircraft, a joint Lockheed Martin/USAF team flying the C-5M Super Galaxy claimed 41 world aeronautical records in one flight. Lockheed says:

“The flight from Dover AFB broke eight existing world marks and established standards in 33 other categories where there had been no previous record attempt. The records were set in the Class C-1.S, Jet category for altitude in horizontal flight, altitude with payload, time-to-climb, time-to-climb with payload and greatest payload to 2,000 meters. The aircraft carried a payload of more than 80,000 kg (the actual measured payload weight was 176,610 lb) to an altitude of more than 41,100 feet in 23 minutes, 59 seconds. . . . It also set marks for time-to-climb and time-to-climb with 35,000 kg (77,162 lb), 40,000 kg (88,185 lb), 45,000 kg (99,208 lb), 50,000 kg (110,231 lb), 60,000 kg (132,277 lb), 70,000 kg (154,323 lb), and 80,000 kg payload. The flight took 4 minutes, 13 seconds to reach 3,000 m (9,843 ft) altitude; 7 min., 27 sec to get to 6,000 m (19,685 ft); 13 min., 8 sec. to fly to 9,000 m (29,528 ft); and 23 min., 59 sec to fly to 12,000 meters (39,371 ft). The flight also broke existing class records for altitude in horizontal flight (41,116 ft) and altitude with 35,000 kg, 40,000 kg, 45,000 kg, 50,000 kg, 60,000 kg, and 70,000 kg payload (41,188 ft). The mission broke the record for greatest payload (80,036 kg/176,610 lbs) to 2,000 meters (6,562 ft) as well.”

Lockheed says the C-5M has greatly improved departure reliability rates (more than 90 percent) as well as providing payload increases of 20 percent over legacy C-5s. With a substantial improvement in unrefueled range, the C-5M is capable of overflying traditional en-route fuel stops, enabling a reduction in fuel consumption by as much as 20 percent.

Sounds to us like the big C-5 is finally starting to earn its substantial paycheck.

–By Jeff Davis, Intergalactic Scribe

Sources:

https://www.lockheedmartin.com/en-us/products/c-5.html

https://www.amc.af.mil/Portals/12/documents/AFD-131018-052.pdf

https://www.wearethemighty.com/mighty-trending/c-5-galaxy-surprising-nickname/

https://www.theaviationzone.com/lockheed-c-5-galaxy/

https://www.defenseindustrydaily.com/saving-the-galaxy-the-c-5-amprerp-program-03938/

https://gizmodo.com/this-was-the-first-plane-to-cost-1-billion-more-than-w-1485831740